Products

What We Do

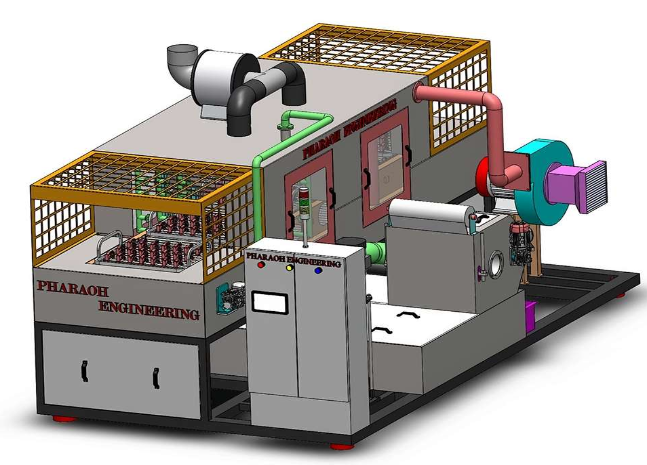

1. Four (4) PE Ultrasonic Washing Machines

All types of designs

2. All Types of Component/Part Oiling Machines

3. 4.0 Industrial Technologies Implementations

a) SPM Robots and Automation for Assembly Line and Conveyor Systems

b) IIoT (Industrial Internet of Things) for Bottleneck, High-Cost Machines, and Process Monitoring Systems

c) Artificial Intelligence for Processes and Machines Where Automation Is Not Working Properly

d) Simulations and Augmented Reality: Real-Time Monitoring and Special-Purpose Testing Machine Design and Manufacturing as per Industrial Requirements

4. Lean Manufacturing Techniques and Systems Implementations

To reduce inventory, manpower, capital, and operating expenses, we optimize processes through layout design, Poka-Yoke implementation, deskilling of operations, bottleneck reduction, and automation.

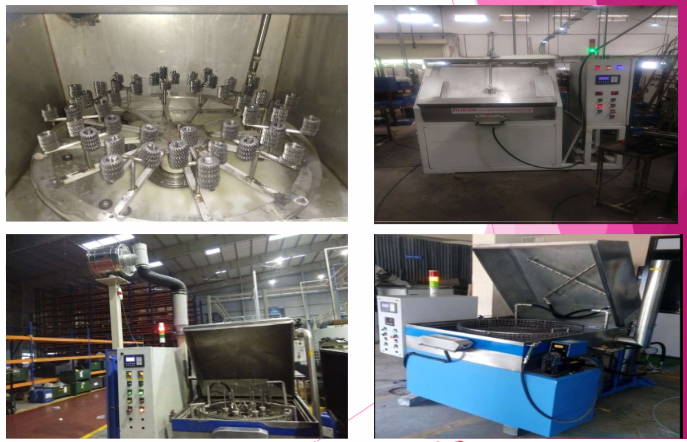

Cabinet Types Parts / bin / tray cleaning machine .

Suitable for batch type production and general / Special cleaning

- Parts to be cleaned are kept on fixture/basket. Basket rotates at low r.p.m. Hot aqueous solution is sprayed over the components through spray nozzles.

- Manual/pneumatic options for opening or closing of canopies/ front door.

- High Pressure Wash(15-18bar)/quick drain- air blow timings can be set and regulated through HMI

- Safe and user friendly for operators

Tunnel type conveyorised parts cleaning like Degreasing -Rinsing – Air blow cleaning machine

Drying of the Parts/bin/try at air blow chamber zone .

- High Pressure jet Continues conveyed or equal indexing type two or three stage coneyorised Parts/bin/ tray cleaning machine with loading at one station and unloading at another station with manual and auto mode operation or by return conveyor .

- PLC controlled electrical panel-advanced conveyor material handling system .

- Compact Paper band filtration system so as arrest the cotton waste .metal particles ,dirt ,grease ,oil etc.(10Micron Paper)

- It is single operator operating machine .

Rotary-indexing multi chamber type parts washers

- Single stage rotary basket ,top loading And unloading specific wash with dedicated nozzle orientation so as to cover entire geometry of the parts and air blow for parts drying during rotation.

- Paper band filtration system to arrest the entire dirt ,grease ,oil etc. on the parts.

- Disk or belt oil skimmer for oil removal

Request a Quote Today

Reach Us

Email :

Pintu@Pharaohrobotic.com